Heat Treatments

Heat Treatments

MW Industries performs hardening, tempering, and annealing for metal components to ensure adequate performance, durability, and cycle life. With decades of experience manufacturing components for various industries and applications and a team of subject matter experts and specialists, we have the know-how to help you determine the right manufacturing and finishing processes to achieve your desired performance even under the most difficult of conditions.

Have questions about this or other services? Ask an MW expert.

一個vailable Heat Treatment Services

-

Hardening & Tempering

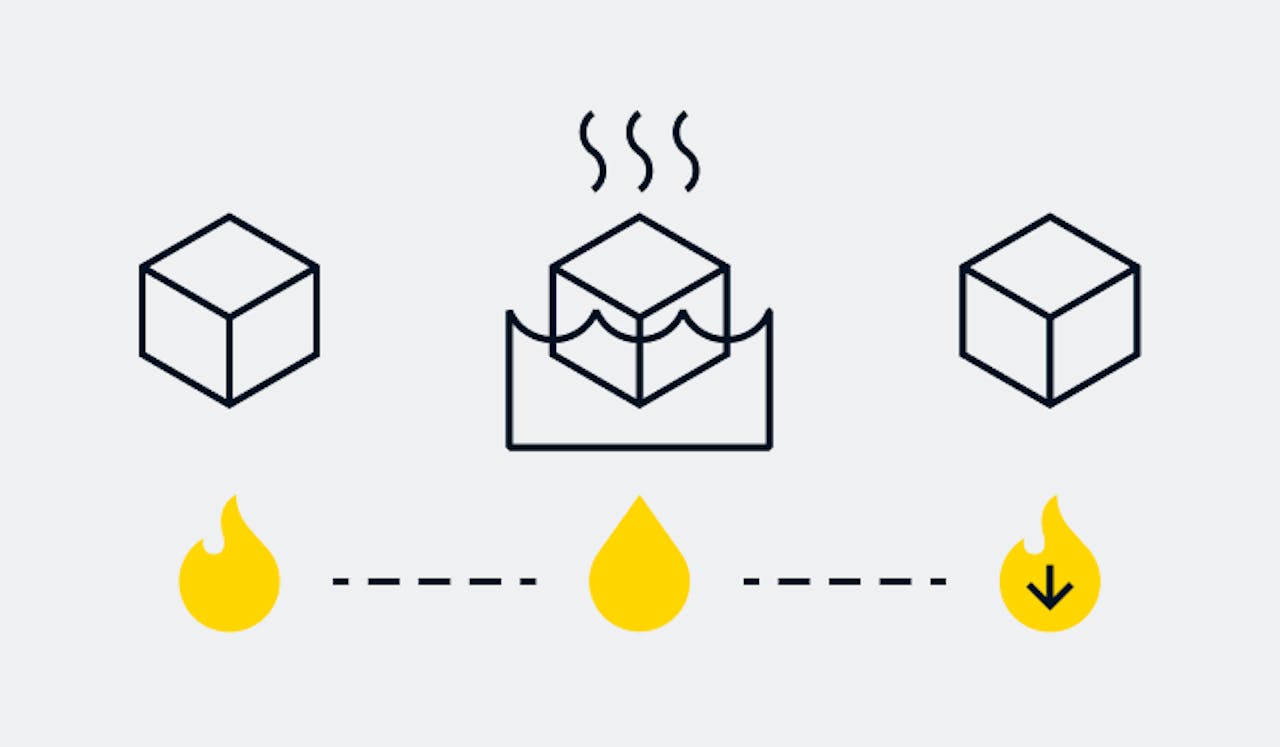

Hardening & TemperingHardening and tempering produce required hardness ratios in metals like steel or stainless steel to ensure desired performance. Harding, as well as case hardening, and straight hardening, involves heating the metal and then cooling it to transform its standard properties, while tempering is a process of applying low-temperature heat treatments, generally after a hardening process has been completed.

-

一個nnealing

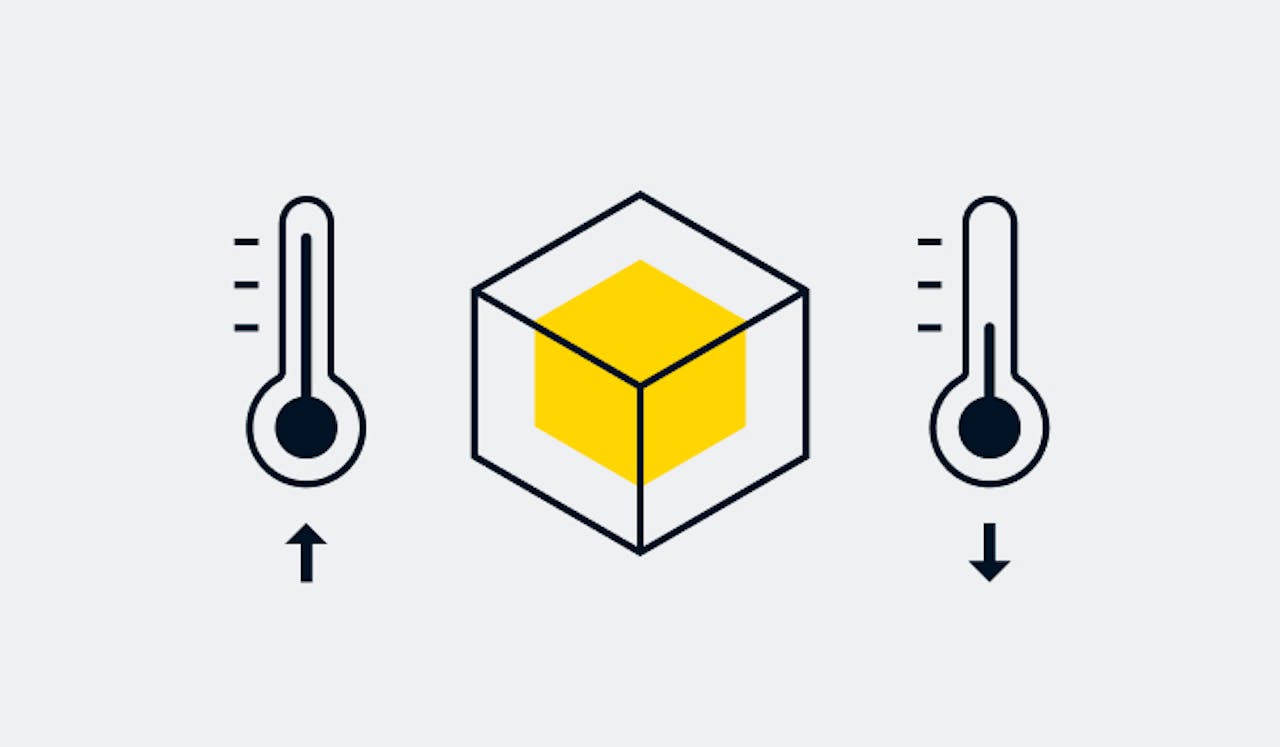

一個nnealing一個nnealing is used to reduce a material's hardness and increase it's ductility by changing its physical and/or chemical properties. Annealing is performed by heating and slowing cooling the material (generally metal or glass).

Industries Served

Heat treatments can be applied to several components in various industries. Below are some of the industries that MW serves.

Ready to Get Started?

Click the button below to request a quote and start your journey with MW.